Neodymium Magnetic Rods for Separation Processes

Neodymium magnetic rods are widely used in separation processes to capture ferrous contaminants from powders, liquids, and slurries. Their high magnetic strength, compact form, and efficiency make them essential in industries such as food processing, mining, plastics, and pharmaceuticals. This article provides a comprehensive overview of how these rods work, their advantages, selection criteria, multi-stage system applications, and comparisons with other magnetic materials.

At Heeger Magnets, we specialize in neodymium magnetic rods, ensuring optimal performance for industrial and scientific applications.

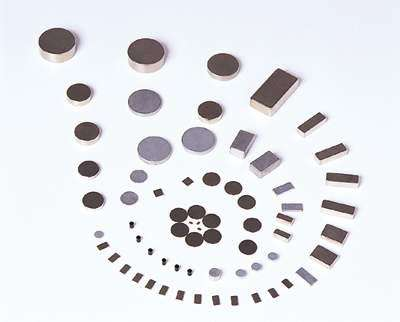

What Are Neodymium Magnetic Rods?

Neodymium magnetic rods are cylindrical devices built from high-strength neodymium magnets encased in stainless steel. They are engineered to attract and retain magnetic particles from materials moving through production lines. Their magnetic field is highly concentrated near the surface, allowing them to capture even micron-sized contaminants.

Typically installed in magnetic filters, separation grids, or processing chutes, these rods help ensure product purity and prevent damage to sensitive equipment. Their compact size and adaptability make them suitable for many types of manufacturing systems.

Key Specifications of Neodymium Magnetic Rods:

| Parameter | Typical Value |

| Magnetic Strength | 9000–12,000 Gauss |

| Diameter Range | 20 mm – 38 mm |

| Length Range | 100 mm – 1000 mm |

| Surface Material | SUS304 / SUS316 Stainless Steel |

| Operating Temperature | ≤ 80°C (standard), up to 350°C (custom) |

Thanks to their high magnetic field, durable casing, and hygienic surface, they are a reliable choice in high-purity separation processes.

Explore our high-quality neodymium magnetic rods.

Why Are Neodymium Magnetic Rods Used in Separation Processes?

Even trace amounts of ferrous material in process lines can reduce product quality, contaminate batches, or damage machinery. Neodymium rods offer a powerful, non-disruptive solution to trap these unwanted particles. Their strong magnetic pull allows continuous collection of contaminants without halting material flow.

They can be installed individually or in banks, depending on the process volume and target particle size. Their modularity allows for easy cleaning, inspection, and maintenance.

Common Separation Applications:

- Food processing lines removing ferrous shavings from powders

- Pharmaceutical plants capture tiny metallic dust

- Plastic recycling systems separating iron particles from granules

- Mining slurries isolating magnetic minerals from ore

- Chemical production removing tramp metals from fluid lines

Their versatility across different systems makes them indispensable in contamination control strategies.

How Do Neodymium Magnetic Rods Compare with Other Magnetic Materials?

Compared to ferrite, Alnico, or samarium-cobalt magnets, neodymium rods offer the highest magnetic strength at a relatively compact size. They are ideal for environments requiring tight tolerances and high purity, although other materials may be preferred in extremely high-temperature conditions.

Comparison of Magnetic Materials:

| Material | Magnetic Strength | Temp Resistance | Cost | Typical Use |

| Neodymium (NdFeB) | Very High | Moderate | Medium | High-efficiency separation |

| Ferrite | Low to Medium | High | Low | General low-cost separation |

| Samarium Cobalt | High | Very High | High | High-temp or corrosive conditions |

| AlNiCo | Medium | High | Medium | Sensors, motors, instruments |

Neodymium magnets offer the best trade-off between cost and magnetic power, making them the preferred option for most modern separation systems.

What Makes Neodymium Magnetic Rods Effective for Powders and Liquids?

Separation processes involving powders or slurries demand precision. Neodymium magnetic rods generate high-gradient magnetic fields that can capture ferrous particles as small as 30 microns, even in fast-moving or viscous flows.

Their non-magnetic stainless-steel casing ensures easy cleaning and compliance with hygiene standards. Often configured in multi-layer grids or inline filters, these rods increase contact area for enhanced efficiency.

Performance Features in Powder & Liquid Separation:

- Magnetic tubes placed in staggered layers increase coverage

- Rods hold magnetic contaminants until manually wiped

- High-intensity magnetic fields remain stable over the years of use

These characteristics make them ideal for high-throughput industrial settings where contamination control is crucial.

What Are the Main Advantages of Neodymium Magnetic Rods?

Neodymium magnetic rods provide a wide range of operational benefits in separation systems.

Top Advantages:

✅ Extremely high magnetic strength for fine contaminant capture

✅ Small, space-saving designs fit into various layouts

✅ Long-lasting magnetic performance with minimal loss

✅ Easy to clean and maintain

✅ Safe for food and pharma use (with SUS316 options)

These strengths make them the go-to choice for enhancing separation efficiency and protecting downstream equipment.

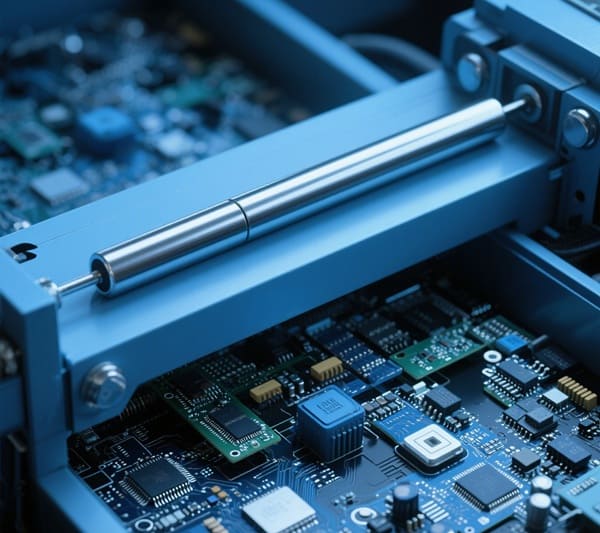

How Are Neodymium Magnetic Rods Used in Multi-Stage Separation Systems?

In modern manufacturing, single-stage separation may not be enough. Neodymium rods are often part of multi-stage systems where different particle sizes and material types are targeted sequentially. This increases capture rates while minimizing cross-contamination risks.

Each stage may use different rod sizes, magnetic strengths, or installation angles depending on the process.

Common Multi-Stage System Configurations:

- Drawer grids in powder hoppers

- Inline magnetic filters for liquids

- Rotary separators with spinning magnetic rods

- Layered grid traps inside pipes

These systems provide scalable solutions for large industrial lines without sacrificing space or efficiency.

How to Select the Right Neodymium Magnetic Rod?

Choosing the proper rod type depends on your product, environment, and system layout. Factors like flow speed, particle size, required strength, and cleaning frequency must all be considered.

Selection Guide by Industry:

| Industry | Recommended Gauss | Surface Material | Key Considerations |

| Food | 10,000–12,000 | SUS316 | Sanitary design, FDA compliance |

| Plastics | 9000–10,000 | SUS304 | Abrasion resistance, durability |

| Mining | 10,000–11,000 | SUS316 | Robust build, slurry compatibility |

| Pharmaceuticals | 11,000–12,000 | SUS316 | High purity, clean-in-place (CIP) |

Rod ends can also be threaded, tapped, or fitted with handles for easier integration and removal.

Request a custom quote for high-quality neodymium magnetic rods.

FAQ

| Question | Answer |

| Can neodymium rods handle high heat? | Standard up to 80°C; custom versions up to 350°C are available. |

| Are they food-grade compliant? | Yes, SUS316 rods meet FDA and GMP requirements for food contact. |

| How often should they be cleaned? | Cleaning frequency depends on contaminant level; weekly is typical. |

| Do they degrade over time? | Magnetic loss is minimal and occurs only under extreme conditions. |

| Can dimensions be customized? | Yes, Heeger Magnets offers custom lengths, diameters, and end fittings. |

These answers help clarify common operational concerns and ensure better implementation.

Conclusion

Neodymium magnetic rods deliver exceptional performance in separation processes where efficiency, safety, and purity matter most. They outperform traditional materials in strength and reliability, with added benefits such as easy maintenance and broad customization. Their widespread use in food, pharmaceutical, plastic, and mining industries highlights their value across diverse sectors.

Heeger Magnets provides high-quality neodymium magnetic rods, customized for your specific process and application. Reach out to our team today to upgrade your separation system with reliable and efficient solutions.

Looking for high-quality neodymium magnetic rods? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104