Exploring Permanent Magnet Motor Technology in Robotics

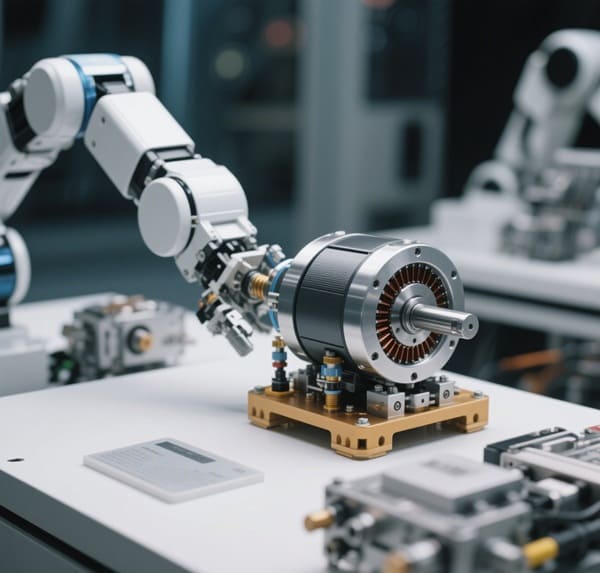

Permanent magnet (PM) motors, powered by rare-earth magnets such as NdFeB and SmCo, offer unmatched power density, precise control, and energy efficiency. These motors are central to the advancement of modern robotics, enabling lighter, more compact, and highly responsive robotic systems—from industrial robotic arms and collaborative robots (cobots) to autonomous drones and medical devices. Their ability to deliver high torque at varying speeds while maintaining reliability in demanding environments makes them ideal for complex robotic applications. This article explores the fundamentals of PM motors, key design considerations, performance benchmarks, real-world applications, and emerging trends shaping the future of robotics.

At Heeger Magnets, we specialize in SmCo magnets and NdFeB magnets, ensuring optimal performance for industrial and scientific applications.

What Is a Permanent Magnet Motor and How Does It Work?

A Permanent Magnet Motor uses magnets on its rotor to create a stable magnetic field without external excitation. These motors—such as PMSM and BLDC—achieve high torque and efficiency due to reduced mechanical complexity. They outperform induction motors in responsiveness and size efficiency.

Comparison of Motor Types:

| Motor Type | Magnetic Source | Efficiency | Control Complexity | Common Use Case |

| Permanent Magnet (PM) | NdFeB or SmCo magnets | High | Medium | Robotics, EVs |

| Induction Motor | Induced electromagnetic field | Medium | Low | Fans, pumps |

| Stepper Motor | Permanent magnets + coils | Low–Mid | High | 3D printers, actuators |

PM motors offer superior efficiency and responsiveness compared to induction and stepper variants, making them ideal for many robotic applications.

What Advantages Do PM Motors Offer in Robotics?

Permanent magnet (PM) motors bring a unique combination of power, precision, and compactness to robotic applications. Their magnetic fields are generated without continuous external excitation, which improves both efficiency and response time, two critical factors in robotic systems where real-time control and energy optimization are essential. Whether in collaborative robots, drones, or surgical devices, PM motors offer a balance of performance and space-saving that traditional motors struggle to match.

Core Benefits of PM Motors in Robotics:

- High torque density: Enables compact yet powerful motor designs, allowing for stronger actuators in smaller frames.

- Compact size: Critical for space-constrained robotic platforms, especially in humanoid robots or miniature drones.

- Superior efficiency: Reduces energy use and heat generation, enhancing battery life and thermal stability.

- Quick dynamic response: Supports agile robotic movements, enabling fast reaction to changing commands or environmental feedback.

- Robust durability: Withstands vibrations, repetitive motions, and rapid load changes common in industrial and mobile robots.

By combining lightweight form factors with performance under stress, PM motors elevate robotic systems to operate with greater intelligence, speed, and precision, paving the way for increasingly autonomous and capable machines.

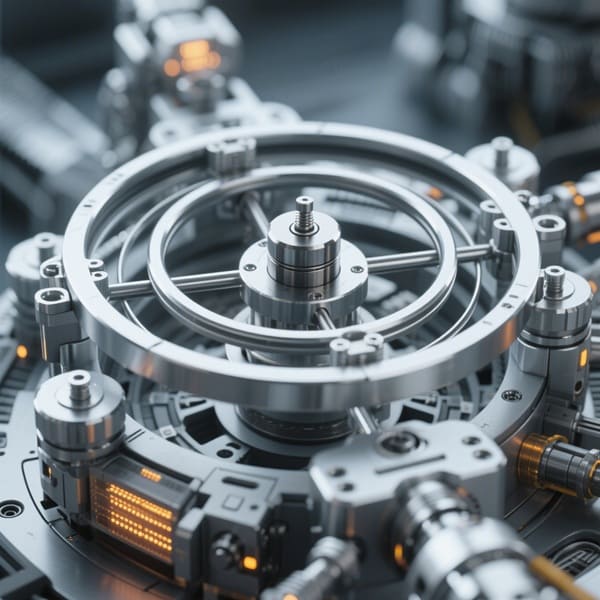

How Are PM Motors Designed and Controlled in Robotic Systems?

Designing PM motors for robotics requires carefully balancing torque, responsiveness, and efficiency through optimized control systems and magnet selection.

Typical PM Motor Control Metrics:

| Parameter | Typical Value | Importance in Robotics |

| Torque-to-weight ratio | >5 Nm/kg | For agile and lightweight robots |

| Response time | <1 ms | Essential for smooth, responsive motion |

| Positioning accuracy | ±0.01° | Required for precision tasks |

Advanced control strategies and accurate magnet placement ensure PM motors meet robotic performance benchmarks.

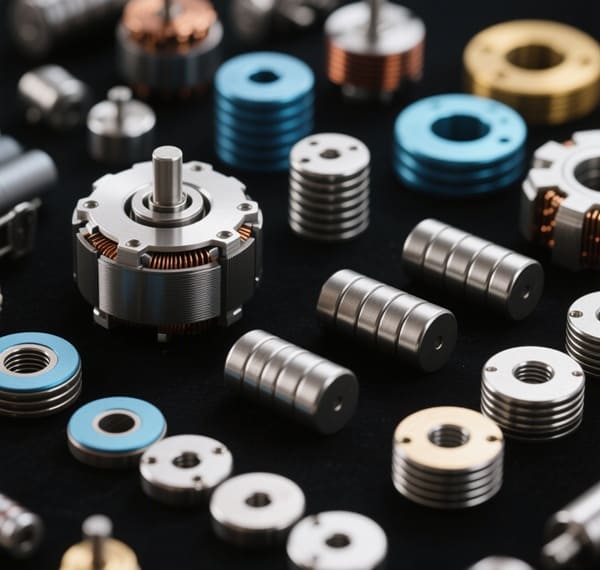

Why Are Rare Earth Magnets (NdFeB, SmCo) Ideal for Robotic Motors?

Rare earth magnets like NdFeB and SmCo are the core components behind the power and efficiency of permanent magnet (PM) motors in robotics. Their high magnetic energy density allows for compact designs, while their stability under heat and stress ensures reliable performance.

NdFeB provides the strongest magnetic output, making it ideal for lightweight, high-torque robotic systems such as drones and servo arms. SmCo, while slightly weaker, performs better in extreme environments due to its high thermal tolerance and corrosion resistance, perfect for aerospace or medical robotics.

Rare Earth Magnet Comparison:

| Magnet Type | Energy Product (MGOe) | Max Temp (°C) | Size Efficiency | Cost Level |

| NdFeB | 35–55 | 150–180 | Very High | Moderate |

| SmCo | 20–32 | 300–400 | High | Higher |

NdFeB suits high-power, space-limited robots, while SmCo excels in heat- and corrosion-prone conditions. Both enable compact, precise, and durable robotic motor designs essential for next-generation automation.

Explore our high-quality SmCo magnet or NdFeB Magnet.

Which Robot Types Use Permanent Magnet Motors?

Different robotic platforms demand performance-driven magnet selection—from nimble humanoids to rugged industrial bots.

Applications in Robotic Systems

| Robot Type | Function | PM Motor Role |

| Industrial Robot | Welding, assembly | Precise servo control |

| Humanoid Robot | Locomotion, dexterity | Agility and control |

| Autonomous Drone | Aerial navigation | Lightweight, efficient propulsion |

| Surgical Robot | Micro-manipulation | Precision and reliability |

| AGV / AMR Robots | Transport, navigation | Durable and efficient drive systems |

PM motors are tailored to each robotic domain, delivering torque, precision, or durability as needed.

What Are the Key Challenges in Integrating PM Motors into Robotics?

Integration of PM motors in real robotic systems presents challenges affecting performance and longevity.

Key Challenges

- Thermal demagnetization: High heat can reduce magnet performance

- Complex control systems: Require precise electronics and tuning

- Cost constraints: High-end magnets add upfront expense

- Sustainability issues: Rare-earth resource availability and recyclability

Designers must account for thermal safeguards, advanced control systems, and sustainable magnet sourcing.

How Does PM Motor Technology Compare to Other Robotic Drive Systems?

PM motors outperform hydraulics and belts when considering power, precision, and responsiveness, but each system has its niche.

Drive System Comparison

| Drive System | Power Density | Precision | Response Time | Robotic Suitability |

| PM Motor | ★★★★★ | ★★★★★ | ★★★★★ | Excellent |

| Hydraulic | ★★★★☆ | ★★☆☆☆ | ★★★☆☆ | Heavy-duty industrial use |

| Belt Drive | ★★☆☆☆ | ★★☆☆☆ | ★★★☆☆ | Cost-effective, light use |

PM motors provide the best balance of power, agility, and precision—ideal for most robotics tasks.

What Is the Future of PM Motors in Robotics?

Trends such as AI-driven design, rare-earth recycling, and next-generation materials will shape PM motor evolution.

Emerging Trends

- AI-optimized motor design: Enhances performance and efficiency

- Dy-free and low-RE magnets: Reduce critical material use

- Magnet recycling programs: Improve lifecycle sustainability

- Integrated micro-drive systems: Compact and efficient actuator units

These trends support smarter, more sustainable, and higher-performance robotic motors in the future.

FAQ

| Question | Answer |

| Do PM motors require regular maintenance? | They are generally low-maintenance. However, bearings and control electronics still require periodic inspection and upkeep. |

| Can rare-earth magnets demagnetize over time? | Yes, especially under high heat or strong opposing magnetic fields. Thermal and electromagnetic shielding is essential. |

| Are PM motors suitable for high-temperature robotic environments? | Yes, especially when using SmCo magnets, which remain stable up to 400 °C. NdFeB requires additional cooling or protective design. |

| Is sensorless control viable for robotic applications? | Yes, but accuracy may decrease slightly. Sensorless strategies rely on back-EMF, which can be challenging in low-speed precision tasks. |

| Can PM motors be used in compact or micro-robotics systems? | Absolutely. Miniature PM motors with NdFeB magnets power micro-drones, surgical tools, and precision actuators. |

Request a custom quote for high-quality samarium cobalt magnets or NdFeB magnets.

Conclusion

Permanent magnet motor technology is revolutionizing robotics—delivering unmatched power, control, and efficiency. NdFeB magnets are the go-to for high-performance, cost-effective applications, while SmCo magnets support high-reliability and extreme-environment systems. As AI, materials science, and sustainable practices evolve, PM motors will continue to define the future of robotic mobility and precision.

At Heeger Magnets, we offer premium rare-earth magnets, customized for your robotics projects. From initial design support to final-grade delivery, our solutions are engineered to elevate your robotic systems.

Looking for high-quality SmCo magnets or NdFeB magnets? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104