What Factors Influence The Durability of Cylinder Magnets?

Cylinder magnets—commonly used in sensors, motors, magnetic separation, and assembly—must maintain performance under stress from temperature, moisture, vibration, and chemicals. Their material integrity, environmental resilience, and mechanical stability directly affect product lifespan, safety, and efficiency. This article examines key durability factors of cylinder magnets, including material selection, production processes, protective coatings, geometric design, environmental exposure, application alignment, and lifespan optimization. Engineers, specifiers, and purchasing teams will gain a deeper understanding of how to achieve reliable, long-lasting performance with cylinder magnets.

At Heeger Magnets, we specialize in various magnet products, ensuring optimal performance for industrial and scientific applications.

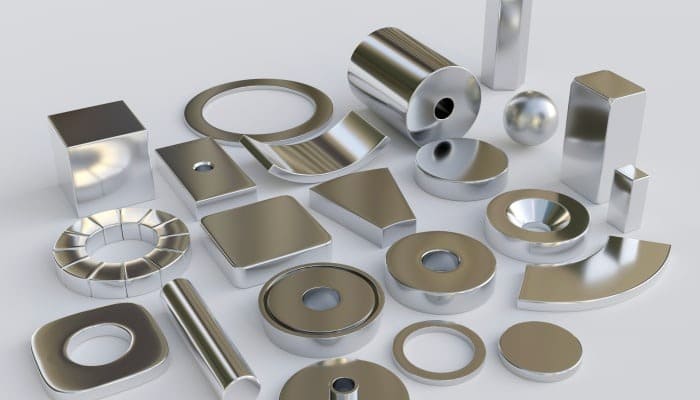

What Materials Are Cylinder Magnets Made Of?

Material composition defines the fundamental attributes of cylinder magnets—magnetic strength, temperature limits, corrosion resistance, and fragility. Three common magnet materials are listed below:

| Material | Remanence (T) | Coercivity (kOe) | Max Temp (°C) | Corrosion Resistance | Typical Applications |

| NdFeB | 1.10–1.40 | 10–30 | 80–150 | Poor—must be coated | Consumer electronics, motors |

| SmCo | 0.90–1.10 | 15–25 | 300–400 | Excellent | Aerospace, medical devices |

| Ferrite | 0.30–0.45 | 3–6 | 200–250 | Good—uncoated optional | HVAC, sensors, noise filtering |

| Bonded NdFeB | 0.70–0.90 | 5–10 | 80–100 | Fair—resin susceptible | Sealed assemblies, low-cost sensors |

- NdFeB offers unmatched magnetic strength but is prone to corrosion and performance loss at high temperatures.

- SmCo is ideal for demanding environments, combining strong magnetic properties with high-temperature and corrosion resistance.

- Ferrite is affordable and rugged, but significantly less powerful magnetically.

- Bonded NdFeB provides flexibility in shape with moderate performance, but its resin binder may degrade over time.

Explore our different shapes of magnet products.

How Do Manufacturing Processes Impact Durability?

Every manufacturing stage plays a crucial role in magnet performance, including:

Key Durability-Influencing Steps:

- Powder Quality & Sintering: Consistent particle size ensures uniform grain growth and optimal coercivity. Poor sintering introduces voids that compromise electric strength.

- Magnetic Alignment Pressing: Cylinders magnetized on precise axes prevent weak zones; misalignment lowers the effective field.

- Stress Relief Annealing: Removes internal stress generated during pressing, reducing the risk of microcracks that could undermine performance.

- Aging or Cryogenic Treatment: Gradually adjusts magnetic domains to stable states, reducing the risk of demagnetization under long-term operation.

By ensuring precise and repeatable production steps, manufacturers can reduce failure rates and extend magnet service lives.

How Do Coatings and Finishes Enhance Durability?

Surface treatments enhance protection from moisture, wear, and other damage sources:

| Coating Type | Corrosion Defense | Wear Resistance | Temperature Limit | Best Use Case |

| Nickel | Excellent | Moderate | ~200 °C | Outdoor, humid, cost-sensitive setups |

| Epoxy | Good | Food, medical, and general industry | ~120 °C | Outdoor humid, cost-sensitive setups |

| Gold | Excellent | Low | ~150 °C | Delicate sensors/instruments |

| PTFE | Excellent | High | ~260 °C | Chemicals, acids, solvents |

Why Coatings Matter:

- Nickel plating provides sanitary-grade corrosion protection, ideal for tablets, food, and pharma.

- Epoxy is flexible and durable, useful for moisture-prone environments.

- Gold offers niche protection for high-precision instruments.

- PTFE resists chemical damage and elevated temperatures, ideal for harsh chemical environments.

Choosing the right coating amplifies a magnet’s effective lifetime in its specific application environment.

Which Environmental Conditions Affect Cylinder Magnet Lifespan?

Environmental stressors can degrade magnet integrity over time:

Common Stressors:

- High Temperature Exposure: Thermal energy weakens magnetic domain alignment—NdFeB demagnetizes after 150 °C if uncoated.

- Moisture & Corrosive Gases: Coating failure can let rust penetrate and degrade internal structures quickly.

- Mechanical Shock & Vibration: Unprotected or poorly designed magnets may chip, crack, or break under mechanical stress.

- Radiation Exposure: In high-energy environments, epoxies used in bonded magnets can break down.

- Abrasion & Chemical Contact: In industrial settings, contaminants can wear down coatings and allow corrosion access.

- Choosing materials and coatings aligned with operational challenges is critical for extending component longevity.

Choosing materials and coatings aligned with operational challenges is critical for extending component longevity.

How Does Geometry Influence Cylinder Magnet Performance?

Shape and dimensions impact both stress distribution and magnetic behavior:

| Design Feature | Durability Impact |

| L/D Ratio | Short, wide cylinders lose magnetization faster; long ones risk mechanical buckling |

| Chamfered Edges | Reduce stress concentration and improve fatigue life |

| Magnetization Style | Radial or segmented approaches can lower stress compared to axial configurations |

| Surface Finish | Smooth surfaces reduce initiation points for cracks and wear |

Design Tip:

Optimized geometry enhances both magnetic performance and mechanical durability simultaneously.

How to Match Cylinder Magnets to Application Requirements?

Selecting the right magnet supports both performance and lifespan.

Material-Environment-Design Checklist:

- High Temp? Use SmCo or high-temperature coated NdFeB.

- Corrosive or Wet Environment? Choose coated NdFeB (nickel/PTFE) or SmCo.

- High Vibration? Chamfer edges + epoxy or robust metal coatings to absorb shock.

- Duty Cycle / Lifetime Requirements? Evaluate aging test results and guarantee parameters.

- Budget vs. Performance: Ferrite offers low cost; SmCo is premium but best for high-demand cases—bonded NdFeB offers a middle ground.

Mapping application parameters to materials, coatings, and design ensures long-term, reliable performance.

Request a custom quote for high-quality magnetic products.

FAQ

| Question | Answer |

| Can cylinder magnets be recoated to extend service life? | Does the cylinder magnet shape influence performance longevity? |

| Does cylinder magnet shape influence performance longevity? | Absolutely—short, wide designs demagnetize faster; edge chamfers and rounded ends improve shock resistance. |

| How long do coated magnets last in humid conditions? | Life expectancy can reach decades with proper coating; uncoated ones may corrode within months. |

| Are cylinder magnets resistant to vibration and impact? | They can be if designed with physical support and protective coatings. Bare magnets are fragile. |

| Which magnets survive high-temperature applications? | Only SmCo and high-temp sealed NdFeB (>300 °C); standard NdFeB degrades rapidly over 150 °C. |

Conclusion

Cylinder magnet durability is the result of careful integration across material selection, production quality, protective treatments, shape engineering, and environment-aware design. Only by aligning these factors to your specific application — ranging from industrial machinery and automation to consumer devices and medical instruments — can you achieve reliable performance and extended lifespan. For expert guidance, custom coating options, and tailored cylinder magnet solutions, Heeger Magnets offers full support and engineering excellence. Let us help you optimize durability and performance in your next project.

Looking for high-quality magnet products? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104