Top 10 Industrial & Scientific Uses for Neodymium Magnetic Rods (2025 Guide)

Neodymium magnetic rods, crafted from the powerful neodymium-iron-boron (NdFeB) alloy, are among the most effective magnetic tools in modern industrial and scientific applications. Known for their exceptional magnetic strength, these cylindrical magnets are designed to deliver focused magnetic fields, making them ideal for tasks requiring precision and efficiency. As industries evolve toward automation, sustainability, and advanced technology in 2025, neodymium magnetic rods are increasingly vital in sectors ranging from food processing to renewable energy.

The unique rod shape of these magnets allows for easy integration into systems where linear magnetic fields are needed, such as filtration or material handling. Their ability to attract and hold ferrous materials with minimal energy input enhances operational efficiency, reducing costs and environmental impact. This guide aims to explore the top 10 industrial and scientific uses of neodymium magnetic rods, highlighting their technical advantages, practical applications, and emerging trends for 2025.

At Heeger Magnet, we specialize in high-quality neodymium magnet rods with various specifications, ensuring optimal performance for industrial and scientific applications.

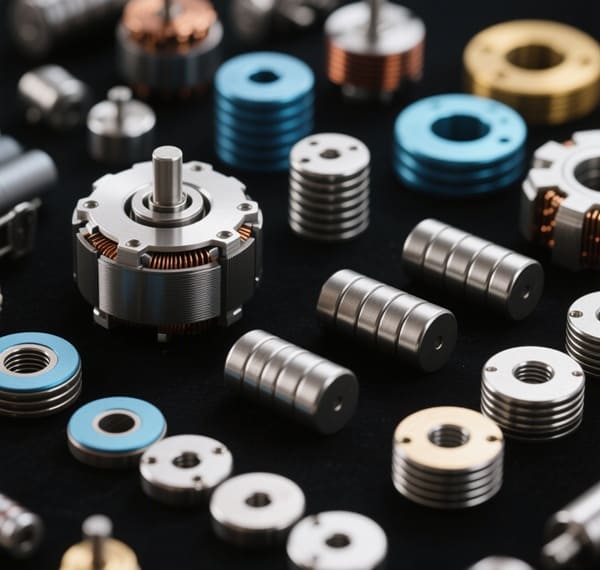

What Are Neodymium Magnetic Rods?

Neodymium magnetic rods are cylindrical magnets made from NdFeB, a rare-earth alloy renowned for its high magnetic strength. The composition of neodymium, iron, and boron creates a crystalline structure that produces magnetic fields far stronger than those of traditional magnets like ferrite or alnico. Typically available in grades such as N35, N42, and N52, these rods offer maximum energy products ranging from 35 to 52 Mega Gauss Oersteds (MGOe), making them among the strongest permanent magnets available.

Their versatility stems from their ability to be customized in size, strength, and coating to suit specific industrial or scientific needs. From small rods used in laboratory stirrers to large ones in industrial separators, neodymium magnetic rods are integral to processes requiring precise control of ferrous materials. Their compact yet powerful design ensures they are a cost-effective solution for enhancing efficiency across various applications.

Key Features:

- High Magnetic Strength – Neodymium magnets generate a powerful magnetic field for their size, often many times stronger than ferrite or alnico magnets.

- Cylindrical Shape – Their rod-like design allows for easy handling, insertion into tubes, or use in linear arrangements.

- Corrosion Resistance – Many are coated with nickel, zinc, or epoxy to prevent rust (neodymium magnets are prone to oxidation).

- Temperature Sensitivity – Standard grades lose strength at high temperatures (typically above 80–150°C, depending on the grade).

The Properties of Neodymium Magnetic Rods:

| Property | Value | Unit | Description |

| Material | NdFeB (Neodymium-Iron-Boron) | The maximum magnetic field a magnet can generate. | Neodymium magnets are made of neodymium, iron, and boron. |

| Magnetic Energy Product | 40-50 MGOe | Mega Gauss-Oersteds (MGOe) | Measures the strength of the magnetic field. Higher values indicate stronger magnets. |

| Maximum Magnetic Field | 1.2 – 1.4 Tesla | Tesla (T) | The diameter of the rod can vary significantly depending on application. |

| Coercivity | 850 – 1,100 kA/m | kA/m | Resistance of the magnet to demagnetization. |

| Residual Flux Density | 1.0 – 1.3 T | Tesla (T) | The magnet’s ability to retain magnetization. |

| Curie Temperature | 310 – 400°C | °C | The temperature above which the magnet loses its magnetism. |

| Density | 7.5 – 8.4 g/cm³ | g/cm³ | The mass per unit volume of the magnet. |

| Pull Force | 5 – 200 kg (depending on size) | kg | The force required to separate the magnet from a flat steel surface. |

| Operating Temperature Range | -40°C to 80°C | °C | The temperature range in which the magnet retains its performance. |

| Size Range | 5mm to 100mm in diameter (varies) | mm | The diameter of the rod can vary significantly depending on the application. |

| Grade | N35 – N52 (Common Grades) | – | Denotes the magnetic strength; higher numbers (e.g., N52) represent stronger magnets. |

| Magnetic Moment | 0.1 – 50 Am² | Am² | The magnetic strength in a specific direction. |

The Grades Comparison of Neodymium Magnetic Rods:

| Grade | Energy Product (BH)max (MGOe) | Intrinsic Coercivity (Hci, kOe) | Max Operating Temp (°C) | Typical Applications | Notes |

| N35 | 35 | ≥12 | 80°C | Hobby projects, basic holders | Cost-effective, moderate strength. |

| N38 | 38 | ≥12 | 80°C | General-purpose uses | Slightly stronger than N35. |

| N42 | 42 | ≥13 | 80°C | Industrial tools, sensors | Popular balance of strength and cost. |

| N45 | 45 | ≥13 | 80°C | High-performance applications | Stronger but more brittle. |

| N48 | 48 | ≥14 | 80°C | Precision instruments | Higher magnetic output. |

| N50 | 50 | ≥14 | 80°C | Specialized industrial uses | Very strong but less stable at high temps. |

| N52 | 52 | ≥14 | 80°C | Maximum strength needs (e.g., research) | Highest grade, but prone to demagnetization if overheated. |

| 35M | 35 | ≥14 | 100°C | Moderate-temperature environments | Improved heat resistance. |

| 38H | 38 | ≥15 | 120°C | Automotive, motors | High coercivity for stability. |

| 40SH | 40 | ≥16 | 150°C | High-temp motors, aerospace | Superior temperature resistance. |

| 42UH | 42 | ≥18 | 180°C | Extreme environments (e.g., turbines) | Ultra-high coercivity. |

| 45EH | 45 | ≥20 | 200°C | Military, aerospace | Highest thermal stability. |

Looking for top-quality neodymium magnetic rods? Explore Heeger Magnet’s selection.

Top 10 Industrial & Scientific Uses of Neodymium Magnetic Rods

Neodymium magnetic rods are indispensable across a wide range of industrial and scientific applications due to their strength and versatility. Below are the top 10 uses, each described in detail to illustrate their impact in 2025.

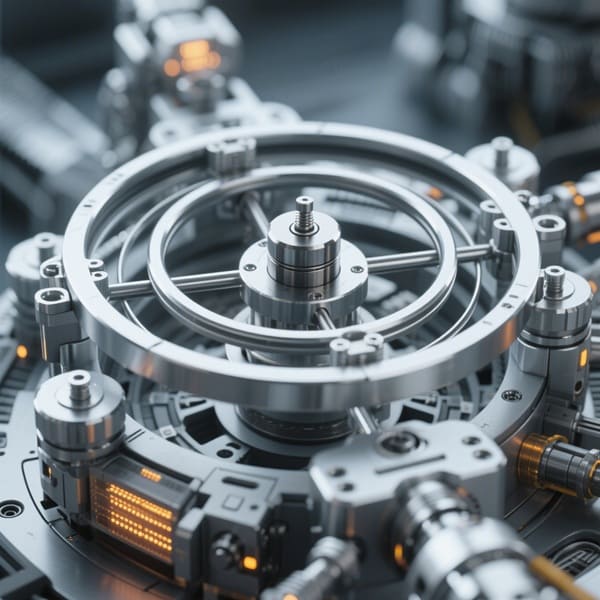

1. High-Precision Motors

Neodymium magnetic rods are widely used in high-precision motors, which are essential in various industries such as robotics, aerospace, and automotive systems. These magnets enable motors to achieve high torque and efficiency in a compact form, making them ideal for use in smaller, high-performance devices.

Applications:

- Robotics: Neodymium magnets are used in robotic actuators, providing precise control over movement. Their small size and strong magnetic field allow for lightweight designs without sacrificing performance.

- Drones: Drones benefit from high-precision motors powered by neodymium magnets, which contribute to the motors’ efficiency and performance, allowing for longer flight times and better maneuverability.

- Electric Vehicles (EVs): The automotive industry, particularly electric vehicle manufacturers, uses neodymium magnets in motors for their high efficiency, contributing to the overall energy efficiency of the vehicles.

By enhancing motor performance and enabling more energy-efficient designs, neodymium magnetic rods continue to drive innovation in industries requiring precision and power in small form factors.

2. Magnetic Separators in Manufacturing

Magnetic separators are essential in various industries, such as mining, recycling, and food processing, where the separation of metal particles from raw materials is required. Neodymium magnetic rods are a key component in these separators due to their strong magnetic fields, which can attract even the smallest metal fragments.

How They Work:

- Mining Industry: Neodymium magnets are used in magnetic separators to extract iron and steel from raw materials, making them more suitable for further processing.

- Recycling: These magnets help separate valuable metal scraps from other materials, enabling efficient recycling processes.

- Food Processing: Neodymium rods are used in food processing plants to remove metal contaminants from food products, ensuring quality and safety.

The strength and durability of neodymium magnetic rods make them indispensable in these applications, helping to increase productivity, reduce contamination, and ensure product safety.

3. Magnetic Resonance Imaging (MRI)

Magnetic Resonance Imaging (MRI) is one of the most important medical imaging techniques, and neodymium magnets play a crucial role in enhancing the performance of MRI machines. The strong magnetic field generated by neodymium magnetic rods allows for high-resolution imaging of the human body, which is vital for diagnosing a wide range of medical conditions.

How Neodymium Magnetic Rods Improve MRI:

- Stronger Magnetic Fields: Neodymium magnets provide stronger and more stable magnetic fields than traditional materials, leading to better imaging quality and clarity.

- Compactness: Neodymium’s high magnetic strength in a small form factor allows MRI machines to be smaller, more efficient, and more cost-effective while maintaining image quality.

MRI technology has revolutionized medical diagnostics, and neodymium magnetic rods have been instrumental in this evolution, helping doctors detect and diagnose diseases with higher accuracy.

4. Scientific Research & Laboratory Instruments

In scientific research, neodymium magnetic rods are crucial for a variety of experiments and applications, particularly in fields like physics, chemistry, and biology. Their strong magnetic fields allow for the precise manipulation of materials and particles in controlled environments, making them indispensable for cutting-edge research.

Applications:

- Particle Manipulation: Neodymium magnets are used to manipulate and control the movement of particles in experiments, such as in particle accelerators.

- Magnetic Traps: Neodymium rods are used in magnetic traps to capture charged particles for analysis.

- Biomedical Research: In biological research, these magnets are used to isolate specific cells or molecules for study.

These applications demonstrate how neodymium magnetic rods are not only essential in industrial settings but also vital in advancing scientific knowledge across many disciplines.

5. Magnetic Stirring in Chemistry

Magnetic stirring is a common technique used in chemistry labs to mix solutions. Neodymium magnetic rods are used to power magnetic stirrers, which can mix solutions without the need for direct contact or mechanical stirring. This method is cleaner, safer, and more efficient.

Benefits:

- Efficiency: Magnetic stirring powered by neodymium magnets is highly efficient, providing consistent mixing without the need for manual labor.

- Non-Contact Mixing: The absence of physical contact reduces the risk of contamination or injury, particularly when working with hazardous chemicals.

- Temperature Control: Magnetic stirrers often come with temperature control features, allowing for precise management of the chemical reactions.

In laboratory settings, magnetic stirring ensures thorough mixing, reduces contamination, and enhances the precision of experiments.

6. Magnetic Levitation Systems

Magnetic levitation (maglev) technology relies on strong magnets, including neodymium magnetic rods, to suspend objects without physical contact. This technology has been used to create highly efficient transportation systems, such as maglev trains, that use magnets to levitate and propel vehicles, reducing friction and enabling high-speed travel.

Applications:

- Maglev Trains: Neodymium magnetic rods are used in the creation of maglev trains, which can travel at speeds of over 300 miles per hour due to the absence of friction between the train and the track.

- Magnetic Bearings: Neodymium rods are also used in magnetic bearings, which eliminate the need for traditional mechanical bearings in high-speed machinery, leading to reduced wear and tear.

Maglev technology offers the potential for revolutionary transportation systems and other applications that benefit from low friction and high efficiency.

7. Electromagnetic Shielding

Neodymium magnetic rods are also used in electromagnetic shielding, where they help protect electronic devices and equipment from harmful electromagnetic interference (EMI). By using magnetic fields to redirect electromagnetic waves, these rods enhance the protection of sensitive devices.

Benefits:

- Improved Device Longevity: By preventing exposure to harmful electromagnetic waves, neodymium magnetic rods help increase the lifespan of electronic components.

- Enhanced Performance: EMI can cause malfunction in devices; magnetic shielding reduces this risk, improving the performance of electronic systems.

In telecommunications, aerospace, and military applications, where EMI is a critical concern, neodymium magnetic rods play a key role in maintaining operational integrity and reducing risks.

8. Sensor Technology

Neodymium magnetic rods are widely used in various sensor technologies. These magnets allow sensors to detect small changes in magnetic fields, which is useful in applications like automotive systems, industrial equipment, and environmental monitoring.

Applications:

- Automotive Sensors: Neodymium magnets are used in sensors that monitor vehicle performance, such as wheel speed and position sensors, ensuring optimal vehicle operation.

- Industrial Sensors: In factories, these magnets are used in position and speed sensors, helping to optimize machinery operation.

- Environmental Monitoring: Neodymium magnetic rods are used in sensors that track magnetic field changes in the environment, aiding in studies related to geology or pollution control.

Sensors powered by neodymium magnets offer precise and reliable measurements in various industries, helping businesses and researchers make informed decisions.

9. Energy Harvesting

Neodymium magnetic rods are increasingly used in energy harvesting systems to generate electricity from mechanical energy. These systems are particularly useful in renewable energy technologies, such as wind turbines and energy converters, where neodymium magnets are employed to convert kinetic energy into electrical energy.

Applications:

- Wind Turbines: Neodymium magnets are used in wind turbine generators to improve energy conversion efficiency.

- Energy Conversion Systems: These magnets are also used in energy converters, where mechanical motion is converted into electrical power.

- Microgeneration: Neodymium magnetic rods are employed in small-scale energy harvesting devices, such as portable generators or wearables that harness human motion.

The use of neodymium magnetic rods in energy harvesting is part of the growing trend toward sustainable, renewable energy sources.

10. Data Storage Devices

Neodymium magnetic rods are widely used in hard drives and magnetic storage devices. With their strong magnetic fields, they improve the precision and speed of data storage and retrieval, thereby enhancing device performance and storage capacity.

Applications:

- Hard Disk Drives (HDDs): Used in read/write heads to improve data transfer speed and storage density.

- Solid State Drives (SSDs): Enhance data access reliability and speed.

- Magnetic Tape Storage: Ensure long-term stability and security of data storage.

The use of neodymium magnetic rods allows data storage devices to continuously break through in both performance and capacity.

Exploring our optimized neodymium magnetic rods.

Benefits of Using Neodymium Magnetic Rods

Neodymium magnetic rods offer significant advantages that make them a preferred choice across industries. Their high efficiency in capturing ferrous particles ensures thorough contaminant removal, critical for applications like food safety and pharmaceutical quality control. A single rod can generate magnetic fields strong enough to trap particles as small as a few microns, enhancing product purity and equipment protection.

Durability is another key benefit, as coatings like stainless steel or Ni-Cu-Ni protect rods from corrosion, extending their service life even in harsh environments like water treatment or chemical processing. Their versatility allows for customization in size, strength, and coating, making them adaptable to diverse applications, from laboratory stirring to industrial lifting. Compared to alternatives like electromagnetic separators, neodymium rods are cost-effective, requiring no power source and minimal maintenance, which reduces operational costs in 2025’s automated systems.

- High efficiency in capturing small ferrous particles.

- Durable with corrosion-resistant coatings.

- Versatile, customizable for specific applications.

- Cost-effective, no power consumption.

At Heeger Magnet, we supply premium-grade neodymium magnets that meet international IEC, ISO, and ASTM standards, guaranteeing exceptional magnetic performance and reliability.

Future Trends for Neodymium Magnetic Rods in 2025

As industries move toward 2025, advancements in coatings, such as improved epoxy and hybrid options, are enhancing the durability and corrosion resistance of neodymium magnetic rods, especially in harsh environments like marine and chemical processing. The integration of smart sensors in applications like magnetic separation is optimizing performance by enabling real-time monitoring, predictive maintenance, and better efficiency in recycling and food processing. Additionally, the rise of green technologies, such as electric vehicles and wind turbines, is increasing demand for these rods in high-efficiency motors. Recycling initiatives driven by concerns over rare-earth material supply chains are also reducing dependence on mined neodymium, supporting both environmental and economic sustainability. These trends position neodymium magnetic rods as a key component for future industrial and scientific applications.

Future Trends:

- Improved coatings for enhanced durability.

- Smart sensors for real-time monitoring.

- Increased use of green technologies (EVs, wind turbines).

- Advances in rare-earth material recycling.

Safety and Handling Guidelines for Neodymium Magnetic Rods

Handling neodymium magnetic rods requires caution due to their strong magnetic fields, which can cause pinching injuries if fingers are caught between rods or metal surfaces. Large rods, with pull forces exceeding hundreds of pounds, pose risks of bruising or fractures. They can also interfere with electronic devices, such as pacemakers or credit cards, necessitating careful handling protocols.

Storage should keep rods away from magnetic-sensitive equipment, using non-magnetic spacers to prevent unintended attraction. During cleaning and maintenance, non-magnetic tools (e.g., plastic or wooden scrapers) should be used to remove trapped debris, avoiding damage to coatings. Regular inspection ensures rods remain free of corrosion or physical damage, maintaining performance.

- Handling: Wear gloves, use non-magnetic tools to avoid pinching.

- Storage: Use spacers, keep away from electronics.

- Cleaning: Remove debris with non-magnetic tools.

- Maintenance: Inspect for corrosion or damage regularly.

Neodymium magnetic rods are a cornerstone of modern industrial and scientific applications, offering unmatched magnetic strength and versatility. From ensuring food safety to powering renewable energy systems, their top 10 uses demonstrate their critical role in driving efficiency and innovation. As industries embrace automation and sustainability in 2025, these rods will remain essential, supported by advancements in coatings, sensors, and recycling.

Selecting the appropriate grade, coating, and size is crucial to optimizing performance for specific applications. Engineers can fully leverage the rods’ benefits by addressing challenges like temperature sensitivity and handling hazards. Looking ahead, neodymium magnetic rods will continue to shape the future of technology, particularly in green energy and smart systems, ensuring their relevance in an increasingly advanced world.

For top-quality neodymium magnetic rods, Heeger Magnet provides tailored solutions for various applications.

Looking for premium neodymium magnets? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104