Neodymium Magnetic Rods for Metal Detection

Neodymium magnetic rods are essential in modern metal detection systems used across food processing, recycling, mining, and pharmaceutical industries. These powerful magnets help detect and remove ferrous and non-ferrous contaminants from material streams, improving product quality and machinery lifespan. In this article, we’ll explore the structure, benefits, working principles, and selection guidelines for neodymium magnetic rods and compare them with other magnet types to support your purchasing decisions.

At Heeger Magnets, we specialize in neodymium magnetic rods, ensuring optimal performance for industrial and scientific applications.

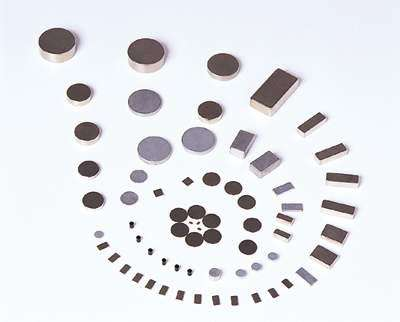

What Are Neodymium Magnetic Rods?

Neodymium magnetic rods are cylindrical magnetic devices made from NdFeB (Neodymium-Iron-Boron), the strongest commercially available rare-earth magnet material. These rods are usually encased in stainless steel to protect against corrosion and mechanical wear. They are integrated into filter housings, magnetic grids, or separator systems where they capture ferrous debris.

The magnetic strength of neodymium magnetic rods enables high capture efficiency, even for very fine metal particles. Their compact shape also allows flexible installation in tight or narrow processing areas.

Key Properties of Neodymium Magnetic Rods:

| Property | Typical Value |

| Material | NdFeB (Grade N35–N52) |

| Magnetic Strength | 10,000–13,000 Gauss |

| Working Temperature | Up to 80°C (standard), 120°C–200°C (custom) |

| Coating/Housing | SUS304 / SUS316 stainless steel |

| Common Sizes | Φ25mm × 100–500mm |

These physical properties make neodymium magnetic rods highly effective for high-speed, high-sensitivity metal separation processes.

Explore our high-quality neodymium magnetic rods.

How Do Neodymium Magnetic Rods Work in Metal Detection?

Neodymium magnetic rods function by generating a strong magnetic field that attracts metal contaminants from flowing material. As raw or processed materials pass around or through the magnetic rod array, ferromagnetic and weakly magnetic particles are drawn to the rod’s surface and held in place.

These rods are typically mounted in grids or cartridges to increase the contact surface area. Periodic cleaning removes trapped contaminants, ensuring consistent performance.

Working Process Overview:

- Material flows past the magnetic rod.

- Magnetic particles are attracted and held.

- Cleaned material continues downstream.

- Magnetic rods are cleaned manually or automatically.

This simple yet highly effective mechanism allows operators to maintain cleaner production lines with less downtime.

What Makes Neodymium Magnetic Rods Effective for Fine Metal Capture?

One of the primary strengths of neodymium magnetic rods is their ability to attract even micron-sized particles. Their high surface field intensity and sharp magnetic gradient allow efficient capture of weakly magnetic materials like stainless steel wear fragments.

Advantages of Fine Metal Separation:

| Feature | Performance Benefit |

| High Gauss levels | Effective against small and low-mass metals |

| Strong surface gradients | Fast attraction speed |

| Stainless steel casing | Durable and food-safe |

| Wide temperature tolerance | Suitable for multiple industrial lines |

This high-resolution detection ability ensures compliance with quality assurance standards in industries like dairy, grain milling, and polymer processing.

Where Are Neodymium Magnetic Rods Commonly Used?

These magnetic rods are widely deployed in any industry where ferrous contamination control is vital. Their effectiveness and compactness make them highly adaptable.

Key Application Areas:

| Industry | Use Case |

| Food & Beverage | Preventing metal in packaged foods |

| Plastic Manufacturing | Protecting molds and extruders from metal wear |

| Mining & Aggregates | Removing tramp iron from crushed ore |

| Recycling | Sorting ferrous materials from shredded streams |

| Pharmaceuticals | Ensuring medical powder and tablet purity |

Their broad utility highlights the importance of neodymium magnetic rods in modern industrial quality control.

How Do Neodymium Magnetic Rods Compare to Other Magnetic Materials?

Comparing neodymium magnetic rods to alternatives like ferrite, samarium cobalt, or alnico reveals major differences in magnetic strength, temperature tolerance, and cost-effectiveness. Each material suits different application environments.

Comparison of Magnetic Materials for Rods:

| Material | Magnetic Strength | Max Temp (°C) | Corrosion Resistance | Cost |

| Neodymium (NdFeB) | Very High (10,000+ Gauss) | 80–200 | Moderate–High (coated) | Moderate |

| Ferrite | Low (2,000–3,000 Gauss) | 250 | High | Low |

| Samarium Cobalt | High (7,000–9,000 Gauss) | 250–350 | High | High |

| AlNiCo | Moderate (5,000–6,000 Gauss) | 450 | Low | Moderate |

While ferrite is suitable for high-temperature or cost-sensitive cases, neodymium remains the first choice for high-efficiency metal detection due to its strength-to-size advantage.

Request a custom quote for high-quality neodymium magnetic rods.

How to Choose the Right Neodymium Magnetic Rods?

Choosing a neodymium magnetic rod depends on the target particle size, processing temperature, flow rate, and space constraints. It’s crucial to match magnet grade, housing type, and rod dimensions with your processing line.

Magnetic Rod Selection Guide:

| Requirement | Recommended Specification |

| High sensitivity | N52 grade, >12,000 Gauss |

| Heavy-duty separation | Custom NdFeB rated for 120–200°C |

| Food safety | SUS316 stainless steel housing |

| Compact installation | Short rod length (100–250mm) |

| Heavy duty separation | Larger diameter (e.g., Φ32mm) |

Consulting with a magnet supplier ensures proper configuration for long-term reliability.

What Are the Benefits and Limitations of Neodymium Magnetic Rods?

Neodymium magnetic rods offer strong separation performance, but they also come with thermal and corrosion sensitivity compared to other options. Understanding the trade-offs is vital.

Pros and Cons of Neodymium Magnetic Rods

| Advantages | Limitations |

| Strongest magnetic field for its size | Lower temperature tolerance than ferrite |

| Captures fine metal particles | Requires protective coating for wet areas |

| Compact and customizable | Costlier than ferrite in some applications |

| Easy to integrate and clean | Not suitable for extreme chemical exposure |

These rods are excellent when performance matters most, but environment-specific considerations are key to success.

Future Trends of Neodymium Magnetic Rods in Metal Detection

With growing demand for food safety, precision manufacturing, and automation, magnetic rod technology is evolving rapidly. New developments in coatings, smart monitoring, and hybrid systems are emerging.

Notable Innovations and Trends:

- Smart Magnetic Grids – Embedded sensors to monitor buildup and trigger cleaning cycles.

- Hybrid Separators – Combining rods with eddy current or optical systems.

- Lead-free Rare-Earth Magnets – Sustainable material developments.

- Miniaturized Rods for Microfluidics – Used in biotech or semiconductor processing.

These advancements will continue improving detection speed, resolution, and safety.

FAQ

| Question | Answer |

| Can neodymium magnetic rods be used in food contact? | Yes, with FDA-grade stainless steel casings. |

| How often should rods be cleaned? | Depends on load; usually every few hours in high-flow lines. |

| Are custom sizes available? | Yes—length, diameter, and casing material can all be customized. |

| Do rods lose magnetism over time? | Very slowly—loss is minimal under proper use conditions. |

Conclusion

Neodymium magnetic rods offer an effective solution for detecting and removing metal contaminants in a wide range of industrial processes. Their strong magnetic field, durability, and ability to capture even fine ferrous particles make them a smart choice for maintaining product purity and equipment safety. As industries continue to demand higher standards, these rods remain a trusted component in separation systems.

At Heeger Magnets, we supply premium neodymium magnetic rods that deliver reliable performance in demanding environments. If you’re looking to improve your metal separation setup, reach out to Heeger Magnets for expert support and custom-engineered solutions.

Looking for high-quality neodymium magnetic rods? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104