How Does the Size of Cylinder Magnets Affect Their Properties?

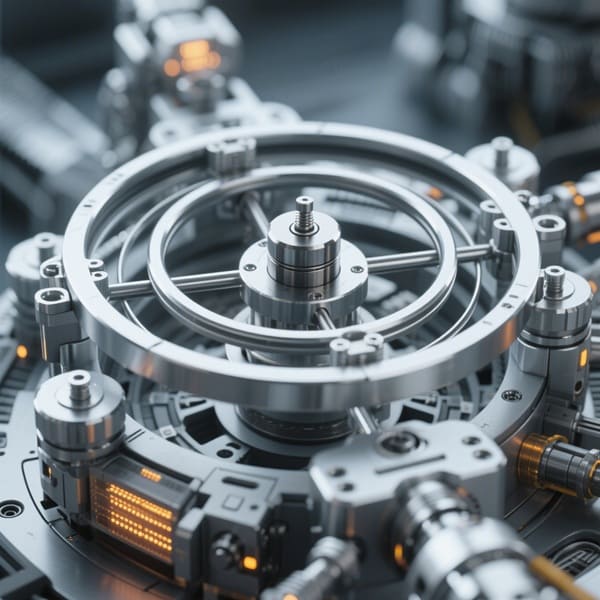

Cylinder magnets, with their unique cylindrical shape, are integral to countless technologies, from electric motors to magnetic resonance imaging (MRI) machines. These magnets, often made from materials like neodymium or ferrite, exhibit fascinating properties that depend heavily on their physical dimensions. The size of a cylinder magnet—its diameter and length—directly influences its magnetic field strength, mechanical durability, and suitability for specific applications. This blog post explores the central question: How does the size of cylinder magnets affect their properties? By examining both magnetic and physical characteristics, we aim to provide a comprehensive understanding of how size impacts performance.

The relationship between their size and magnetic properties is complex, with larger magnets generally offering stronger fields and increased resistance to external influences like temperature and pressure. However, smaller magnets can offer unique advantages in specific use cases. By examining how these properties change with size, we can better design and apply cylinder magnets to meet the demands of diverse technological and industrial needs.

At Heeger Magnets, we specialize in cylinder magnets, ensuring optimal performance for industrial and scientific applications.

Overview of Cylinder Magnets

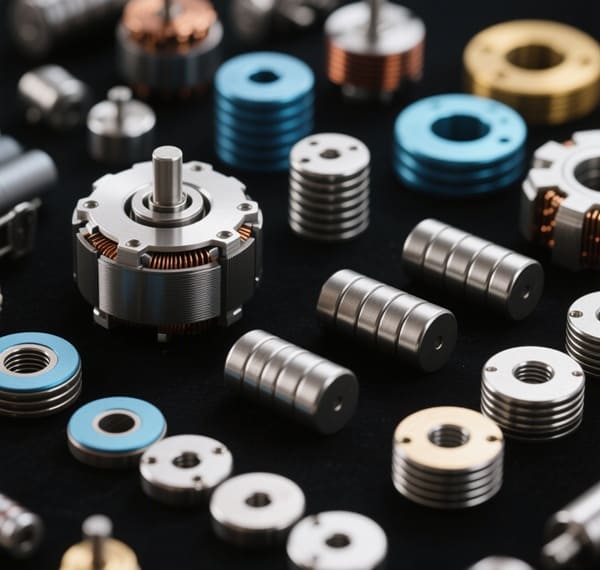

Cylinder magnets (also called rod magnets or cylindrical magnets) are a common type of permanent magnet characterized by their round, rod-like shape. They are widely used in industrial, electronic, and mechanical applications due to their strong magnetic fields, compact size, and versatility.

1. Common Magnetic Materials

| Material | Properties | Max. Operating Temp. | Typical Applications |

| Neodymium (NdFeB) | Extremely strong, brittle, corrosion-prone | 80°C – 220°C (depending on grade) | Motors, sensors, holding systems |

| Samarium Cobalt (SmCo) | High temperature resistance, corrosion-resistant | 250°C – 350°C | Aerospace, military, and high-temperature environments |

| AlNiCo | Good temp. stability, lower coercivity | 450°C – 550°C | Sensors, instruments, and older motors |

| Ferrite (Ceramic) | Economical, corrosion-resistant, weaker | 250°C – 300°C | Speakers, fridge magnets, educational kits |

2. Magnetic Properties

✅ Magnetization Direction

Cylinder magnets can be magnetized in two primary ways:

- Axial Magnetization (through the length) → Poles on the flat circular faces.

- Diametric Magnetization (through the diameter) → Poles on the curved sides.

✅ Magnetic Strength (Gauss & Tesla)

Measured in Gauss (G) or Tesla (T) (1 T = 10,000 G).

Depends on:

- Material (Neodymium > SmCo > Alnico > Ferrite).

- Grade (e.g., N52 neodymium is stronger than N35).

- Size-to-Strength Ratio (thicker magnets usually have higher pull force).

✅ Coercivity & Remanence

- Coercivity (Hc) – Resistance to demagnetization (high in SmCo & NdFeB).

- Remanence (Br) – Residual magnetism after external field removal.

✅ Pull Force (Holding Strength)

- Measured in kilograms (kg) or pounds (lb).

- Example: A 10mm diameter x 5mm thick N52 magnet can hold ~1.5 kg.

Looking for top-quality cylinder magnets? Explore Heeger Magnet’s selection.

How Does Size Affect Magnetic Performance?

The magnetic field strength of a cylinder magnet is profoundly influenced by its size, specifically its diameter and length. Larger magnets, with greater volume, can accommodate more magnetic domains, resulting in a stronger magnetic field. For instance, a neodymium cylinder magnet with a diameter of 10 cm and a length of 20 cm will produce a significantly stronger field than one with a 1 cm diameter and a 2 cm length. However, the relationship is not purely linear. The aspect ratio (length-to-diameter) plays a critical role. A long, thin magnet (high aspect ratio) generates a more focused field along its axis, while a short, wide magnet (low aspect ratio) produces a broader, less intense field.

This behavior can be explained by the magnet’s demagnetizing field, which opposes its magnetization. In larger magnets, the demagnetizing field is less dominant, allowing for a stronger net field. Engineers must consider these factors when designing applications. For example, in electric motors, larger magnets with optimized aspect ratios are used to maximize torque, while in magnetic sensors, smaller magnets with precise fields are preferred.

1. Magnetic Field Strength and Distribution

The magnetic field of a cylinder magnet is influenced by its size (diameter and length) and magnetization direction (axial or diametric).

- Field Strength: For a given material (e.g., neodymium), a larger cylinder magnet produces a stronger magnetic field than a smaller one because it contains more magnetized material.

- Field Uniformity: The field is most uniform near the central region of the magnet’s pole faces, with flux lines spreading outward.

- Range of Influence: Larger magnets exhibit a longer effective range—their field extends farther from the surface before decaying.

Example:

- A 10mm diameter × 10mm long N52 magnet generates a stronger and more extended field than a 5mm × 5mm magnet of the same grade.

2. Coercivity: Resistance to Demagnetization

Coercivity (Hc) measures how well a magnet resists demagnetization from external fields, heat, or mechanical stress.

✅ Size Impact: Larger magnets generally have higher coercivity because their greater volume provides more magnetic domain stability.

✅ Material Dependence:

- Neodymium (NdFeB): High coercivity but degrades at elevated temperatures.

- Samarium Cobalt (SmCo): Exceptional coercivity, even in extreme environments.

Practical Implication:

A thicker cylinder magnet is less likely to lose magnetization when exposed to opposing fields than a thinner one of the same material.

3. Magnetic Moment: Torque and Work Capacity

The magnetic moment (μ) quantifies a magnet’s ability to generate torque or interact with external fields.

✅ Formula: μ=M×V

- M = Magnetization (material-dependent)

- V = Volume of the magnet

✅ Size Effect: A larger cylinder magnet has a greater magnetic moment because its volume increases, amplifying its influence on nearby magnetic materials.

Example:

- A 20mm long × 10mm diameter magnet has 8x the magnetic moment of a 10mm × 5mm magnet (assuming the same material and grade).

4. Magnetic Saturation: Maximum Magnetization

Saturation occurs when a magnet’s domains are fully aligned, and no further magnetization is possible.

✅ Size Dependency:

- Larger magnets require stronger external fields to reach saturation due to their higher volume.

- Once saturated, they maintain stable magnetic output unless subjected to extreme conditions.

✅ Material Differences:

- Neodymium: Saturates at ~1.2–1.4 Tesla.

- Ferrite: Lower saturation (~0.4 T), making it less powerful.

Explore our optimized cylinder magnets.

Effect of Size on Physical Properties of Cylinder Magnets

The size of a cylinder magnet directly affects its weight, as larger magnets have greater volume and mass. For instance, a neodymium magnet with a diameter of 5 cm and a length of 10 cm can weigh significantly more than one with a 1 cm diameter and 2 cm length. This increased weight impacts the magnet’s suitability for applications where portability or minimal mass is critical, such as in drones or wearable devices.

Density, however, remains constant for a given material, so the weight increase is purely a function of volume. We must balance magnetic strength with weight constraints. For example, larger magnets may be used in automotive applications for their strength, but their weight could reduce fuel efficiency.

1. Mechanical Strength & Durability

✅ Brittleness Scaling:

- Small magnets (<5mm diameter) are more prone to chipping/cracking during handling

- Larger magnets (>15mm) better withstand mechanical stress but are more vulnerable to internal flaws

✅ Impact Resistance:

- Force tolerance increases with cross-sectional area (∝diameter²)

- Example: A Ø10mm magnet can typically withstand 2-3× the impact force of a Ø5mm magnet

2. Thermal Management

✅ Heat Dissipation:

- Larger volumes provide better thermal mass, slowing temperature changes.

- Surface-area-to-volume ratio affects cooling rates: Small magnets heat/cool faster, and large magnets maintain more stable temperatures.

✅ Critical Size for Demagnetization:

- Below ~3mm thickness: Rapid heat transfer increases temp-related demagnetization risk.

- Above ~10mm: Thermal gradients become significant in pulsed applications.

How to Choose the Right Size of Cylinder Magnets?

1. Define Your Primary Requirement

Start by identifying the most critical need:

- Strong Holding Force → Prioritize diameter (more material = stronger field)

- Precision Positioning → Focus on length-to-diameter (L/D) ratio for field shape control

- High-Temperature Stability → Increase volume to resist demagnetization

- Space Constraints → Optimize for compactness with multiple small magnets

2. Key Size Selection Factors

| Factor | Small Magnets (Ø<10mm) | Large Magnets (Ø>20mm) |

| Field Strength | Weaker, localized field | Stronger, longer-range field |

| Mechanical Strength | Fragile (handling challenges) | Robust but heavy |

| Thermal Stability | Prone to rapid temp changes | Better heat resistance |

| Cost Efficiency | Lower material cost | Higher material usage |

- For holding applications, the diameter should be ≥75% of the target object’s width.

- For sensing/positioning, match the magnet size to the sensor active area.

3. Material-Specific Considerations

A. Neodymium (NdFeB) Magnets

- <5mm diameter: High risk of chipping – use protective coatings

- >50mm diameter: Requires special sintering – longer lead times

- Optimal L/D ratio: 1:1 to 2:1 for balanced performance

B. Ferrite Magnets

- <3mm diameter: Difficult to magnetize effectively

- >100mm diameter: Common for speakers/motors

C. Samarium Cobalt (SmCo) Magnets

- <2mm diameter: Limited availability

- >25mm diameter: Extremely expensive

4. Practical Selection Workflow

✅ Calculate Required Force (if applicable):

- Use pull force calculators (e.g., K&J Magnetics)

- Add a 20-30% safety margin

✅ Determine Space Limitations:

- Max dimensions for housing

- Clearance for magnetic field interactions

✅ Evaluate Environmental Factors:

- Temperature → Larger sizes for high-temp stability

- Vibration → Thicker magnets resist cracking

✅ Prototype Testing:

- Test 2-3 sizes in real conditions

- Measure field strength with a Gauss meter

5. Common Mistakes to Avoid

❌ Oversizing: Wastes material and increases assembly difficulty

❌ Undersizing: Fails to meet performance requirements

❌ Ignoring L/D Ratio: Results in poor field distribution

❌ Neglecting Coatings: Leads to corrosion in small magnets

6. Quick Reference Table

| Application | Recommended Size | Material |

| Sensor triggers | Ø3-6mm × 2-5mm | NdFeB/N42 |

| Cabinet latches | Ø10-15mm × 5-10mm | Ferrite |

| Motor rotors | Ø20-50mm × 10-30mm | NdFeB/N35EH |

| High-temp fixtures | Ø15-25mm × 10-20mm | SmCo |

At Heeger Magnet, we supply premium-grade cylinder magnets that meet international IEC, ISO, and ASTM standards, guaranteeing exceptional magnetic performance and reliability.

The size of cylinder magnets plays a pivotal role in determining their magnetic and physical properties, influencing everything from field strength to thermal stability. Larger magnets offer stronger fields but face challenges like non-uniform magnetization, brittleness, and poor heat dissipation. Smaller magnets, while more uniform and mechanically robust, may lack the power needed for heavy-duty applications. By understanding these size-dependent effects, designers and engineers can make informed decisions to balance performance, cost, and practicality. Whether powering a tiny sensor or a massive motor, the right magnet size is key to success.

This exploration underscores the importance of tailoring magnet size to specific needs, ensuring optimal performance across diverse applications. Future advancements in materials and manufacturing may further refine these relationships, opening new possibilities for cylinder magnets in technology and industry.

For top-quality cylinder magnets, Heeger Magnets provides tailored solutions for various applications.

Looking for premium cylinder magnets? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104