Types of Rare Earth Magnets Used in Permanent Magnet Motors

Rare earth magnets like NdFeB and SmCo have revolutionized permanent magnet motors by delivering extremely high magnetic strength and efficiency. They enable lighter, more compact, and more powerful motors, key for applications ranging from electric vehicles and robotics to wind turbines and aerospace systems. This article dives into the main rare earth magnet types used in motor design, compares their performance characteristics, and explains how to choose the right magnet based on specific motor requirements.

At Heeger Magnets, we specialize in SmCo magnets and NdFeB magnets, ensuring optimal performance for industrial and scientific applications.

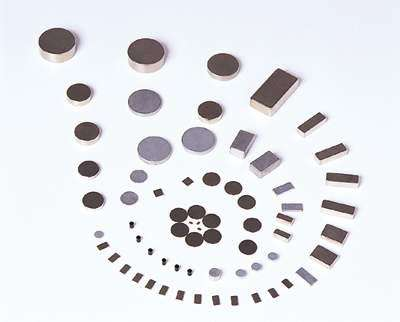

What Are Rare Earth Magnets?

Rare earth magnets are alloys primarily composed of neodymium (Nd), samarium (Sm), and other elements like iron, cobalt, and boron. Their high magnetic energy density and stability make them the backbone of high-performance motors.

Common Types of Rare Earth Magnets:

| Magnet Type | Composition | Max Energy Product (MGOe) | Typical Use |

| NdFeB | Nd₂Fe₁₄B | 35–55 | EVs, robotics, consumer motors |

| SmCo | SmCo₅ / Sm₂Co₁₇ | 20–32 | Aerospace, defense, precision motors |

| CeFeB | Ce/Fe/B low-cost | ~15–25 | Budget-friendly consumer devices |

NdFeB provides the highest magnetic energy and global volume usage, SmCo excels in thermal stability and harsh environments, and CeFeB offers a cost-effective solution for less demanding applications.

How Do Permanent Magnet Motors Work?

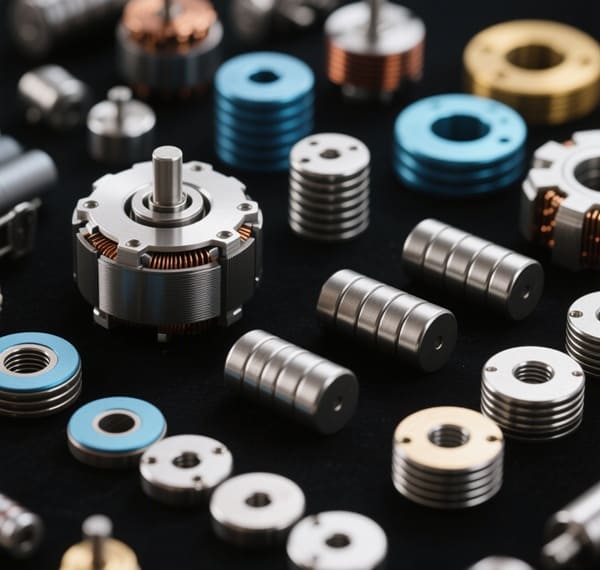

Permanent magnet motors—like PMSM and BLDC—use magnets on the rotor to create a rotating magnetic field, eliminating the need for rotor windings. This simplifies the design, improves efficiency, and increases torque per weight.

Key Motor Types Using Rare Earth Magnets:

- PMSM (Permanent Magnet Synchronous Motor): Used in electric vehicles and industrial drives for precise control

- BLDC (Brushless DC Motor): Common in consumer electronics, tools, and small appliances

- Stepper Motors: Used for high-accuracy positioning in robotics and instrumentation

Permanent magnet motors rely heavily on the magnet’s ability to maintain strong, stable fields, translating directly into efficiency, precision, and compactness.

What Are the Key Properties of Rare Earth Magnets for Motors?

Choosing the right magnet material for a motor isn’t just about magnetic strength—it’s about achieving the right balance between energy density, operating temperature, durability in harsh environments, and overall lifecycle cost. Different magnet types offer trade-offs, especially when used in electric vehicle motors, aerospace actuators, or high-speed industrial equipment.

Below is a comparative overview of NdFeB and SmCo magnets based on performance parameters most relevant to motor engineering.

| Property | NdFeB | SmCo |

| Max Energy Product | ★★★★★ (35–55 MGOe) | ★★★★☆ (20–32 MGOe) |

| Temperature Stability | ★★☆☆☆ (<150 °C without advanced design) | ★★★★★ (up to 350–400 °C) |

| Corrosion Resistance | ★★☆☆☆ (requires coating or plating) | ★★★★☆ (intrinsic resistance) |

| Mechanical Strength | ★★★★☆ (good) | ★★★★★ (high and stable) |

| Cost per kg | ★★☆☆☆ ($50–80) | ★★★★☆ ($120–180) |

Summary: NdFeB magnets deliver high magnetic performance at a lower cost, making them the default choice for many general-purpose motors. However, their thermal and corrosion limitations mean they require protective coatings and smart motor design. SmCo magnets, while more expensive, provide superior thermal stability and corrosion resistance—vital in high-temperature, mission-critical environments like aerospace and medical systems.

Explore our high-quality SmCo magnet or NdFeB Magnet.

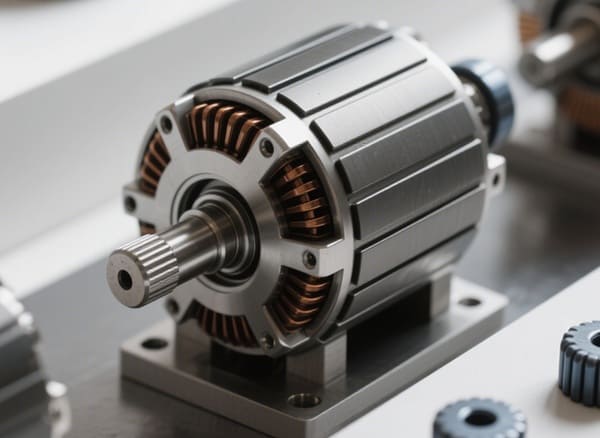

Why Are Rare Earth Magnets Ideal for High-Performance Motors?

Rare earth magnets—particularly Neodymium Iron Boron (NdFeB) and Samarium Cobalt (SmCo)—have transformed how motors are designed across industries. Their exceptional magnetic strength and material stability allow engineers to build motors that are smaller, lighter, faster, and more efficient. This makes them essential for next-generation applications like electric vehicles, drones, precision robotics, and aerospace systems.

These magnets provide a powerful combination of physical and functional advantages that standard ferrite or AlNiCo magnets simply cannot match.

Core Advantages in Motor Applications:

- High torque density: Delivers more torque per unit volume, enabling compact, powerful motors.

- Compact motor design: Allows for reduced weight and space, critical for mobile or embedded systems.

- Improved thermal performance: Maintains magnetic integrity even at elevated operating temperatures.

- Durable under stress: Performs reliably under mechanical vibration, shock, and variable loads.

- Extended lifespan: Demonstrates excellent resistance to demagnetization, ensuring consistent output over time.

By combining superior energy product values with thermal and structural resilience, rare earth magnets empower motor designers to meet increasingly demanding performance targets—whether it’s in EV drivetrains or aerospace guidance systems. Their adoption continues to grow as motor technologies evolve toward greater efficiency and integration.

NdFeB vs. SmCo: How to Choose the Right Rare Earth Magnet for Your Motor?

Choosing between NdFeB and SmCo depends on your application’s thermal, cost, and environmental requirements. The table below outlines the key differences for informed decision-making.

NdFeB vs SmCo in Motor Applications:

| Factor | NdFeB | SmCo |

| Heat Resistance | Up to 150 °C | Up to 350–400 °C |

| Cost per kg | $50–80 | $120–180 |

| Torque per Volume | Very high | Moderate |

| Risk of Demagnetization | Higher | Lower |

| Corrosion Resistance | Requires coatings | Naturally resistant |

Select NdFeB for cost-effective, high-power, moderate-temperature applications. Choose SmCo for high-temperature, corrosion-prone, or reliability-critical environments, despite its higher price.

Request a custom quote for high-quality samarium cobalt magnets or NdFeB Magnets.

Where Are These Magnets Used in Practical Motor Applications?

Rare earth magnets such as neodymium (NdFeB) and samarium cobalt (SmCo) are essential in advanced motor technologies. Their powerful magnetic properties enable compact, high-efficiency motor designs across industries. The choice between NdFeB and SmCo depends on operating conditions, like temperature extremes, corrosion exposure, or precision requirements.

Applications of Rare Earth Magnets in Motors:

| Industry | Motor Use Case | Common Magnet Type |

| Electric Vehicles | Traction drives, auxiliary motors | NdFeB |

| Aerospace | Actuators, flight-control systems | SmCo |

| Robotics | Joint motors, sensor drives | NdFeB / SmCo |

| Medical Devices | Surgical micro-motors | SmCo |

| Industrial Machinery | CNC spindles, vacuum pumps | NdFeB |

This table illustrates how magnet selection aligns with real-world performance demands. NdFeB magnets are favored where compact size and strong output are essential at scale. SmCo magnets are used where temperature stability, corrosion resistance, and long-term reliability are non-negotiable.

FAQ

| Question | Answer Summary |

| Are rare earth magnets replaceable in motors? | No—they are integrated into rotor design and not easily swapped out. |

| Can SmCo replace NdFeB in all motor types? | Do rare-earth motor magnets need EMI shielding? |

| How is NdFeB corrosion prevented? | Yes, especially in sensitive electronics or high-EMI environments. |

| Typically, through Ni or epoxy coatings. | Typically,y through Ni or epoxy coatings. |

| What is the lifespan of rare-earth motor magnets? | Typically between 10–20 years, depending on conditions and maintenance. |

Conclusion

Rare earth magnets—NdFeB and SmCo—are essential to the advancement of permanent magnet motor technology. NdFeB offers high magnetic strength at a competitive cost, making it suitable for EVs, robotics, and industrial drives. SmCo, on the other hand, thrives in high-temperature, corrosive, or mission-critical environments like aerospace and defense. Choosing the right magnet means aligning key properties—like thermal limits, torque needs, and long-term stability—with the motor’s application demands.

At Heeger Magnets, we offer premium NdFeB and SmCo magnets that meet strict performance standards for today’s high-efficiency motors. With support for custom grades, shapes, and coatings, we help you optimize your design for reliability and performance, now and into the future.

Looking for a high-quality SmCo magnet or NdFeB magnets? Contact us today!

Call us now: 925-385-8104

Call us now: 925-385-8104